Applicable Industries:

Manufacturing Plant

Showroom Location:

Turkey, Indonesia, Thailand, Colombia, Kazakhstan, Uzbekistan

Video Outgoing-inspection:

Provided

Machinery Test Report:

Provided

Marketing Type:

Ordinary Product

Warranty Of Core Components:

1 Year

Core Components:

PLC, Engine, Bearing, Gearbox

Condition:

New

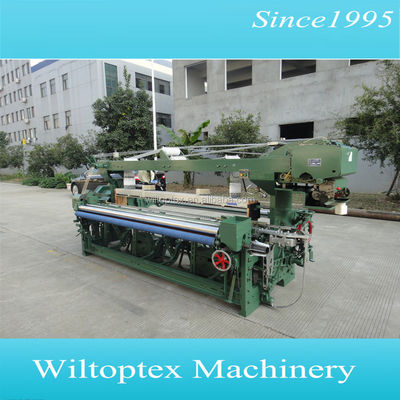

Type:

Rapier Loom

Application:

Weaving All Kinds Fabrics, Weaving All Kinds Of Fabrics

Production Capacity:

3000 Sets/year

Dimension(L*W*H):

450*250*260cm

Weight:

2.0 KG

Power:

1.5~2.2kw

Warranty:

1 Year

Key Selling Points:

Automatic

After-sales Service Provided:

Engineers Available To Service Machinery Overseas, Free Spare Parts, Video Technical Support, Online Support, Field Installation, Commissioning And Training, Field Maintenance And Repair Service

Weaving Machine:

Special Fabrics Rapier Loom

Reed Width:

230cm 260cm 280cm 330cm 360 Cm

Shedding Motion:

Mechanical Dobby

Weft Selection:

4 Color, 6 Color

Let Off Motion:

Electronic Let Off Motion

Take Up Motion:

Continuous Gapless Take Up Moiton

Shedding Type:

Cam Or Mechanical Dobby

After Warranty Service:

Video Technical Support

Local Service Location:

Sri Lanka

Certification:

ISO9001 : 2008

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!